Electrogenics Labs

MOSkin™ Radiation Dosimetry System

2023

ISO 13485:2016 - Research, Concept, Development, Prototype + Packaging

Next Generation Precision Radiation Dosimetry

MOSkin™ Revolutionising Quality Assurance in Radiation Therapy — Simple, Fast & Accurate in-vivo Dosimetry

Electrogenics Labs is set to transform medical radiation therapy on a global scale by enhancing the quality and safety of treatments through an accurate, affordable patient skin dose measurement platform — MOSkin™. This system is being commercialised in collaboration with Design + Industry, Genesys Electronics and the University of Wollongong, and leverages a technical breakthrough in MOSFET (Metal Oxide Semiconductor Field Effect Transistor) dosimeter detector and packaging technology. This technology, developed at the Centre for Medical Radiation and Physics at the University of Wollongong, measures integrated radiation dose, and Electrogenics has exclusively acquired the global licence for its commercialisation. The MOSkin™ system addresses one of the most pressing challenges in contemporary medical radiation therapy — the lack of a precise, easy-to-use method for clinicians to ensure accurate dosage delivery to the correct location for each patient, every time. Beyond its role as a measurement tool, MOSkin™ functions as a crucial quality assurance device that enhances control over radiation dosage, consequently, having the potential to improve patient outcomes. MOSkin™ sets itself apart by streamlining the process, significantly reducing the time and effort that clinicians must spend with currently available market products and approaches thanks to its D+I engineered, user-centred design.

The MOSkin System is currently in development with an established pathway towards regulatory approval for commercial clinical use.

The Complex World of Radiation Oncology

The Urgent Need for Efficient, User-friendly, and Cost-effective Dosimetry Tools

There are approximately 20 million patients diagnosed with cancer every year. Radiotherapy is recommended for over 50% of these patients – about 10 million new patients per year. Underdosing can result in complications, recurrence or reduced tumour control. Overdosing can result in skin burns and radiation toxicity requiring skin grafts. Radiation oncology relies heavily on Linear Accelerators (LINACs), machines that deliver intense radiation doses in cancer treatment. Ensuring the LINAC's output accuracy is paramount and involves complex quality assurance procedures, typically through in vivo dosimetry using tools like Thermoluminescent Dosimeters (TLDs) or diodes. Despite their common use, these tools carry significant inefficiencies. TLDs are robust but require up to 24-hours for result processing, with complex processing equipment + methods that make them prone to human error and costly for healthcare providers. Diodes provide immediate results but pose their own problems: they require patient-uncomfortable cabling during treatment, lack accuracy in skin dose measurements, and are incompatible with specific immobilisation devices. Each of these tools adds to operational expenses and mandates regular quality assurance checks. Such complexities in an environment where precision and patient comfort are paramount highlights an immediate need for a user-friendly, cost-effective, and efficient solution.

Developing a Reliable + Desirable Solution

Optimised Usability, Operability, Desirability and Manufacturability

To kick-start the development of the MOSkin™ system, D+I embarked on an extensive research phase to shape the system's conceptual direction. The aim was to create a unique, cohesive product design language that facilitated a superior user experience, reducing the chance of use errors and time to results, while embodying a high-value aesthetic — a tangible reflection of the cutting-edge technology at the heart of MOSkin™. Balancing quality with affordability, D+I honed the usability and operability of the MOSkin™ system. A key focus was placed on optimising the product's design for manufacture, emphasising ease of assembly and cost-effectiveness to ensure suitability for high-volume production, a critical factor underpinning the solution's scalability.

MOSkin™: An Integrated Solution

Accurate Radiation Dosimetry Through Cohesive Sensor, Hub, and Reader Integration

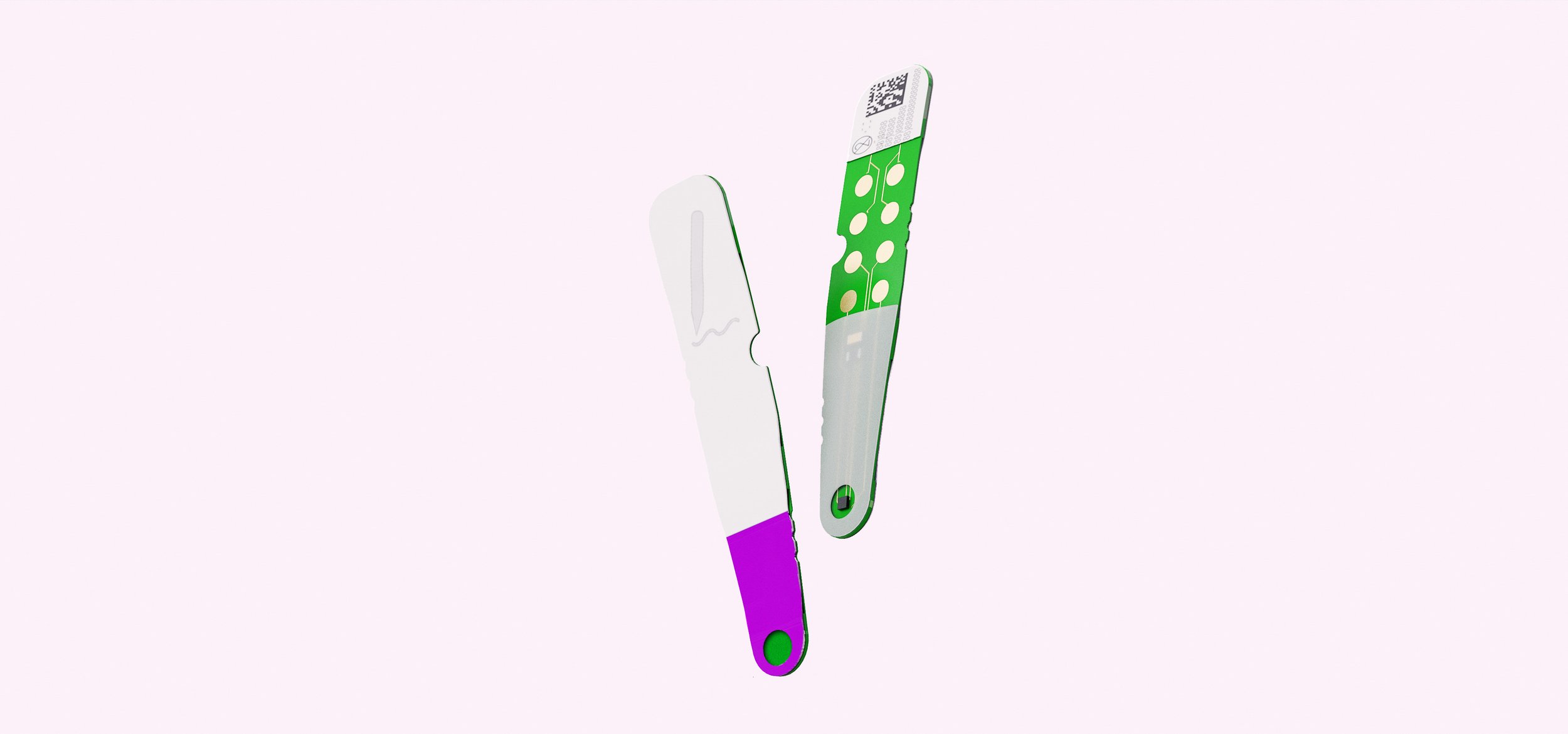

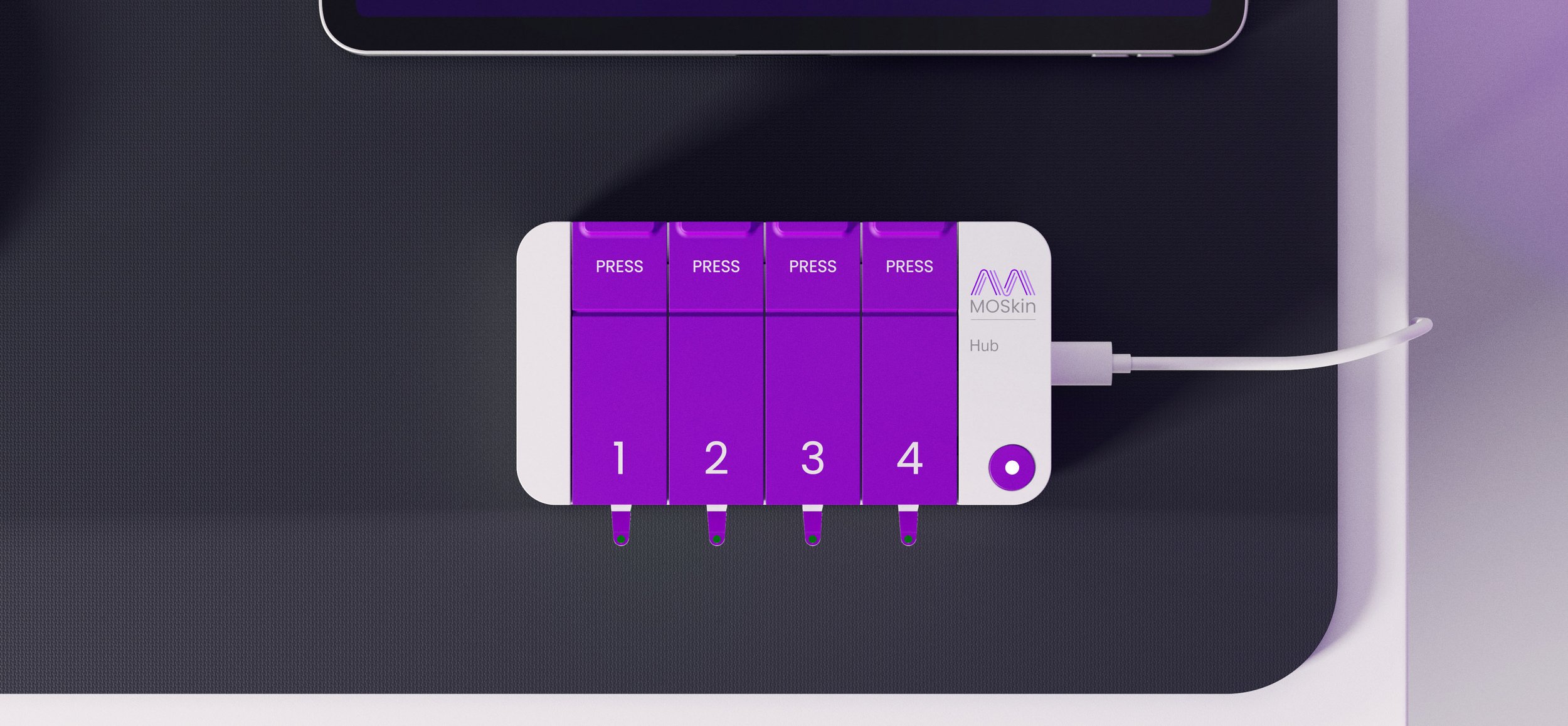

The MOSkin™ Sensor is a single-use device adhered to the patient's skin, capturing the cumulative radiation skin dose over the treatment duration. Embedded within a polyamide medium, this sensor is robust and environment-protected, capable of real-time in-vivo dosimetry without interfering with the treatment process. The Single Use sensor is pre-calibrated at manufacture, ready for use straight out of the pack. Following treatment and data transfer, the sensor can either be disposed of into clinical waste or stored for patient records. The MOSkin™ Hub is a self-powered, wireless device capable of activating and syncing up to four MOSkin™ Sensors simultaneously. It reads information from the sensors and relays it to the MOSkin™ Reader for clinical review. The MOSkin™ Reader is an iPad application that displays the patient's radiation measurements captured by the MOSkin™ Sensors. It also assigns unique identifiers and geographical placement locations to each of the sensors for each patient. The application offers seamless navigation through setup, patient management, and data capture sequences. The collective functionality of these elements ensures an effective and efficient radiation treatment process. The integrated system of the MOSkin™ Sensor, Hub, and Reader delivers unparalleled quality assurance, while working in harmony with the Hospital system and current processes. MOSkin™ allows clinicians to effectively monitor and manage radiation dosage, ensuring optimal patient outcomes.

MOSkin™ Radiation Dosimetry System

A User-friendly, Cost-effective Solution Optimising Patient Outcomes

The MOSkin™ system presents a ground-breaking solution that directly addresses the needs of users in radiation oncology. It simplifies complex procedures and enhances quality assurance with unparalleled precision and efficiency. By revolutionising in-vivo dosimetry, the MOSkin™ system transcends traditional methods, offering a more user-friendly, cost-effective, and efficient solution. This technological advancement goes beyond improving operational processes - it paves the way for a new era in radiation treatment, ensuring that each of the 90 million treatment sessions delivered annually achieve optimal patient outcomes.

[ RESEARCH USE ONLY - PENDING REGULATORY CLEARANCE ]