Inventia Life Science

RASTRUM™ Allegro

2025

Concept, Development + Production

D+I Part of Capgemini: Life Science Device Design & Engineering

RASTRUM™ Allegro: Produce your own 3D cell models in minutes

Product Development: Industrial Design + Mechanical Engineering

The next-generation platform transforming 3D cell culture for drug discovery and disease research: Engineered to meet the demands of drug discovery and translational research, RASTRUM Allegro delivers the reproducibility and scalability you need to advance your research. By streamlining the creation of 3D cell models, it empowers you to optimize therapeutic strategies and accelerate your path to discovery.

RASTRUM™ Allegro is engineered to help researchers produce their own 3D cell models in minutes, meeting the scalability and reproducibility demands of modern drug discovery and translational research. By streamlining 3D cell culture workflows, Allegro supports high-throughput screening and accelerates the path to meaningful insights, enabling scientists to recreate complex tissue and tumour microenvironments with precision.

Powered by drop-on-demand bioprinting technology and precision robotics, RASTRUM Allegro delivers a 96-well plate in just six minutes (and a 384-well plate in nine), enabling up to 35+ plates in a standard eight-hour day. This efficiency is coupled with consistently low variability, ensuring post-print CVs below 10% and downstream assay CVs below 19%. By minimising dead volume, Allegro lets researchers make the most of every sample—including patient biopsies—often producing 3.5 times more models from limited cell inputs.

Returning after the successful development of the first-generation RASTRUM™ platform, Inventia engaged D+I to support the design of the next-generation Allegro system. The focus was on refining the product design language, optimising internal component configurations for the enhanced high-throughput printing technology, and improving device usability based on researcher feedback and workflow requirements. The result is a sleek, modular aesthetic featuring a striking combination of silver, black, and Inventia’s subtly textured anodised pink aluminium, paired with high-gloss pink-tinted glass viewing panels with rear-printed black sections—providing a window into the 3D bioprinting process. The form factor builds on the previous generation, balancing corner radii and fascia edges while maintaining a compact, lab-optimised footprint. Clearly defined top vents integrate technical refinement with a key functional requirement—efficient airflow management.

A key advancement over the first-generation RASTRUM™ is the redesigned front access panel, developed in collaboration with Inventia’s engineering team. While Inventia defined the underlying mechanism and functionality, D+I refined the exterior configuration, optimising the panel’s form, integration, and manufacturability. This improvement enhances accessibility, minimises interference with adjacent lab equipment, and enables single-handed plate loading and unloading. Below the panel, an intuitive interface with illuminated status indicators (Power, Ready, Active) provides immediate visual feedback, ensuring clear system status at a glance. Positioned to the right of the interface, a single power button reinforces ease of use, evoking a console-style layout that enhances familiarity and intuitive operation. D+I employed 3D surface modelling and virtual real illustrations to refine form transitions and maintain visual coherence, while ergonomic anthropometric analyses informed the placement of access points and the final design of the sliding panel mechanism—ensuring seamless operation for researchers during extended discovery sessions.

Behind Allegro’s modern exterior is a focus on both usability and design for manufacture and assembly (DFMA). Working closely with Inventia’s engineering teams, D+I optimised internal configurations to reduce bench-space requirements while maximising functional density. Components were standardised wherever possible, enabling scalable production and straightforward maintenance. A key focus was achieving precise alignment and tolerancing between glass and aluminium interfaces, ensuring seamless integration and aesthetic consistency. This involved a global supplier search, with extensive sampling and QA/QC testing across multiple glass manufacturers before final selection. In exploring alternative design concepts for subsystems like the printhead enclosure, the teams arrived at a robust system that supports reproducible drop-on-demand bioprinting with minimal operator intervention.

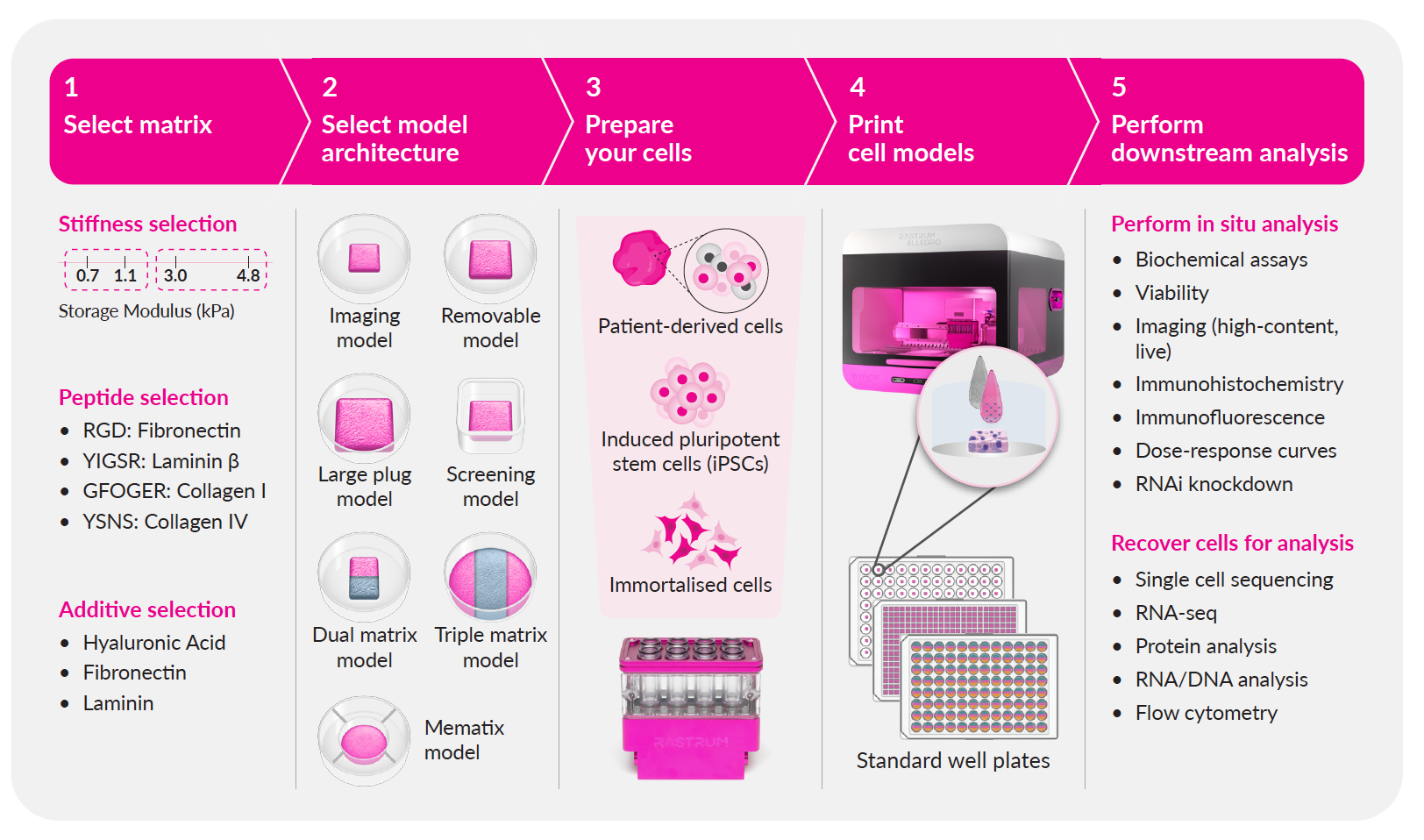

Workflow Diagram — How it works:

Allegro’s workflow ties these design elements together, from selecting a matrix in the expansive, xeno-free library to preparing cells and printing 3D models via a simple, point-and-click interface. Once printed, researchers can seamlessly integrate high-content imaging and other downstream analyses, backed by Allegro’s standardised layouts and minimised variability. By uniting advanced bioprinting technology with an evolved industrial design, RASTRUM Allegro positions scientists to explore disease mechanisms, test therapeutic strategies, and ultimately accelerate the development of new treatments—making the leap from concept to discovery faster and more reproducible.

Learn more about RASTRUM™ Allegro at inventia.life

From idea to impact — Learn more about New Product Development at D+I Part of Capgemini